The Toyota Way: 14 Principles from the World's Greatest Manufacturer

My review of the 2nd edition, thoughts, recommendations, plus an FAQ for interested readers.

The book covers the 14 principles behind the “The Toyota Way”. The Toyota Way was formally introduced by Fujio Cho, then CEO, in 2001. Each chapter explains a principle with examples and stories of real-life work at Toyota. The principles describe how Toyota became a learning organization and a world-leading manufacturer. I recommend this book to anyone interested in studying Lean and how it may apply to other industries (i.e software delivery).

Listen to a simplified version of this post. Originally published on Small Batches.

The Toyota Way House

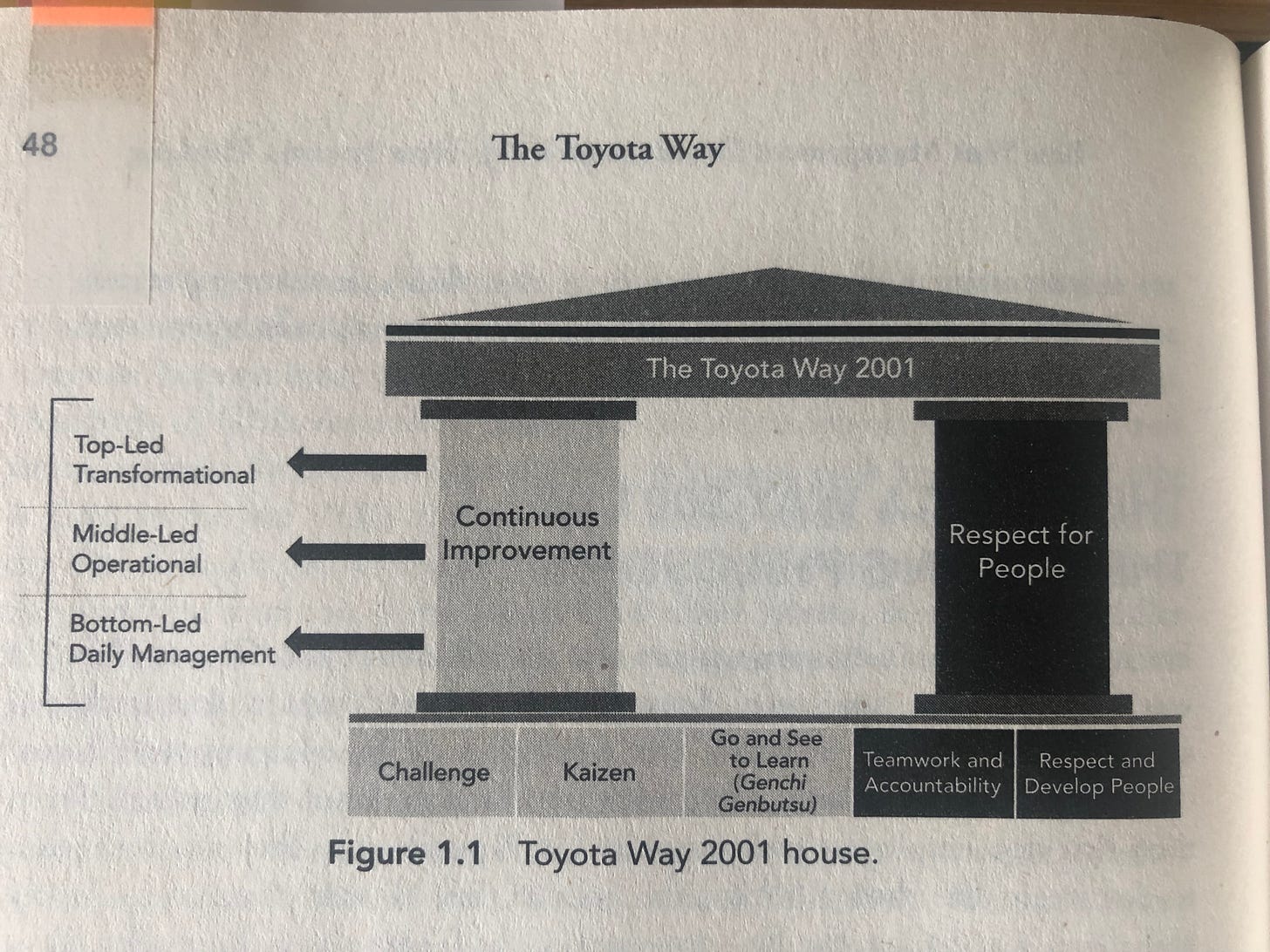

“The Toyota Way” (the concept, not the book) may be visualized as a house with two pillars. One pillar is continuous improvement or kaizen. Challenge everything. Learn. Explore. Discover. The second pillar is respect for people. Toyota believes its people can rise to any challenge and equips them with the philosophy and organizational support to do so.

The book breaks The Toyota Way into fourteen principles categorized by the 4Ps: Philosophy, Process, People, and Problem-Solving.

The fourteen principles overlap with the four capabilities (system design, problem-solving, knowledge sharing, and teaching others) introduced in The High-Velocity Edge. There is a strong Deming influence in them all because he worked extensively with Toyota.

Also, the second edition of this book was updated to factor in Mike Rother’s work in The Toyota Kata. If you’re familiar with these books or listened to the related Small Batches episodes, you’ll feel right at home with these principles. In fact, they may not even be a surprise.

I’ve paraphrased the principles a bit to fit this format better.

Philosophy

Principle One: Adopt systems thinking. Take a long-term view and focus on the entire end-to-end value stream. Do not prioritize short-term results.1

Process

Principle Two: design systems for flow and identifying problems. The key to this principle is the second part. Systems need built-in mechanisms (jidoka) to solve surface problems. That’s the first step in solving them.2

Principle Three: use pull-based systems. “Pull” in the Toyota Way means the ideal state of just-in-time manufacturing: giving the customers what they want, when they want it, and how much they want. This is the foundation for all future lean processes.3

Principle Four: level the work to create flow. Toyota calls this heijunka. The idea is to manage incoming work to meet demand and ensure minimal interruptions. Unleveled work creates waste by underutilizing resources or overburdening them. Level the work, then just-in-time begins to take on meaning.

Principle Five: standardize work as the foundation for continuous improvement. Continuous improvement, or kaizen, only works if there is a baseline. Standardizing work means codifying the best way to do something as it’s currently understood. “Currently” is the operative word in that sentence.

Principle Six: stop and fix problems when they occur. This is the follow-up to principle two. Stop and fix the problem as early as possible in the process. Toyota’s Andon cord is an example.4

Principle Seven: use visual control to support decision-making and problem-solving. A picture is worth a thousand words. Human beings’ strongest sense is The visual sense. Leverage that. Display the state of the system and processes in useful visuals so people can quickly assess the situation and make necessary adjustments.

Principle Eight: smart humans with robot friends. Toyota uses technology to support its people and processes. They do not introduce technology for technology’s sake. They tend to be behind the adoption curve but that’s OK with it.

People

Principle Nine: grow leaders who understand the work, live the philosophy, and teach it to others. Toyota leaders are coaches. They deeply understand systems thinking, continuous improvement, and dedicated practice. Their job is to teach others to do the same.5

Principle Ten: develop people and teams who follow the company philosophy. Toyota needs people who can follow the principles and internalize the culture.

Principle Eleven: help and improve value chain partners. Toyota views itself as having a learning relationship with its partners. It makes sense because if partners improve their value chain, the end-to-end value chain is better for the customer.

Problem-Solving

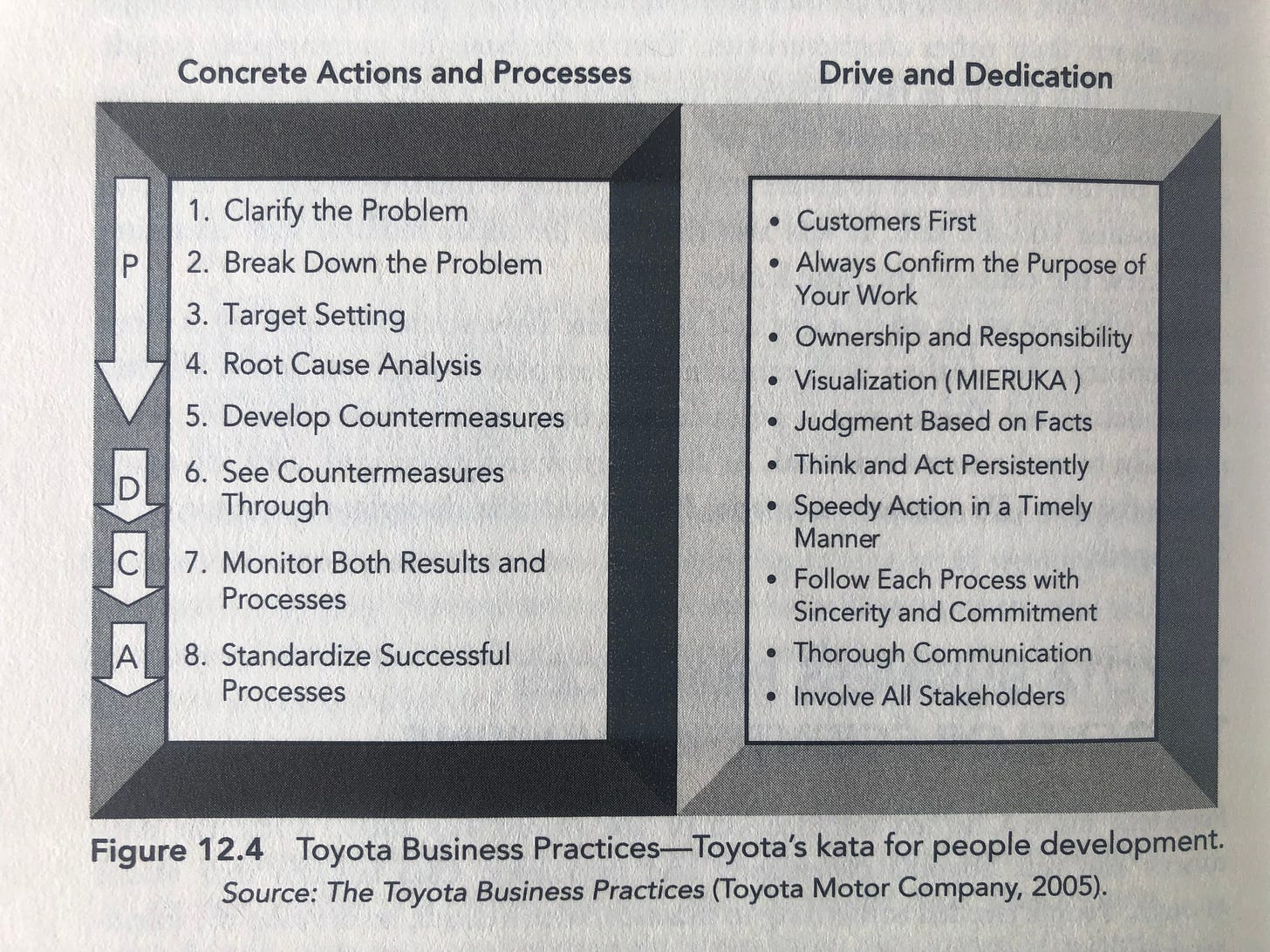

Principle Twelve: PDCA everything. Plan-Do-Check-Act everything, everywhere, all the time. Think scientifically about the current condition and how to reach the target condition.6

This means continuous improvement or kaizen. Standardized work provides the backstop for new experiments. Regression is not possible. Instead, empirical results guide continuous improvements.

Principle Thirteen: align the improvement energy of people through all levels. Engage people top-down, bottom-up, and horizontally. Challenge people and give them the autonomy required to rise to the task.

Principle Fourteen: learn your way to the future in small batches7. What a lovely principle, right? Experiment your way forward through constant iterations. Set bold targets, then get there one batch at a time. This connects back to principle one: adopt long-term systems thinking. That provides the time and mindset to iterate in small batches over the years.

These principles underpin two other Toyota-isms: The Toyota Production System and the Toyota Business practices.

Toyota Production System & Toyota Business Practices

You’ve likely heard of the Toyota Production System (or TPS). That’s their manufacturing process. The Toyota Business Practices (or TPB) are newer and apply across all of Toyota.

Here is Liker’s definition of TPS:

TPS is Toyota’s unique approach to manufacturing and the basis for much of the lean production movement that has dominated manufacturing and service trends for the last 30 years or more. Led by Taiichi Ohno, TPS was constructed in a time of low demand and a high need for vareity in Japan, which necessiated a manufacturing apporach that allowed for quick changeovers, low inventories, and flexibility.

Based on the philosophies of jidoka and just-in-time, TPS can effeciently and quickly produce products of sound quality, one at a time, that fully statisfy customer requirements.

Basically, it’s how Toyota makes cars and why this book even exists. Toyota would not be Toyota as we know it today without TPS.

Toyota is not immune from growing pains. Their international growth made it difficult to maintain a coherent culture. Fujio Cho, then CEO, led the introduction of The Toyota Way (pictured earlier) in 2001.

He realized this was insufficient to help employees develop a continuous improvement mindset and respect for people and processes. He introduced the Toyota Business Practices as a framework for developing Toyota Way thinking across the entire company.

This graphic wonderfully summarizes the practices: PDCA guides action with proper intention. You can see the Toyota Kata applied as well.

My Thoughts

The stories and alternate explanations of concepts I’d encountered elsewhere are my favorite part of the book.

Most of my education about Toyota came from indirect sources. So, I figured I’d go straight to the source. The book definitely delivered on that. This book is 100% Toyota.

The principles did not surprise me, but the book’s graphics and explanations did. I liked the Toyota Way 2001 House. It wonderfully depicts the philosophy. There’s also another graphic of the Toyota Production System as a PDCA loop overlayed with jidoka and just-in-time.

I came away with a newfound appreciation for terms I’d encountered before. The first is gemba (you may know “gemba walk”) and genchi genbutsu.

“Gemba” roughly translates to the place where the work actually happens.

[Taiichi] Ohno admonished his students to “observe the production floor without preconceptions and with a blank mind. Repeat why five times to every matter.”

Notice that Ohno says “observe”. It’s not enough to simply go. You must observe and study the actual condition.

You must unlearn what you have learned. You cannot approach the gemba with assumptions. One first admits they do not fully comprehend the current condition. Thus, going to the gemba is a learning exercise. First, understand the current condition. Then, progress toward the target condition.

There’s a wonderful quote somewhere that you cannot learn something you think you already know. This is similar to a zen saying8:

“You are like this teacup, so full that nothing more can be added. Come back to me when the cup is empty. Come back to me with an empty mind.”

The focus on gemba stuck with me, so I applied it in my work. My practice was to avoid assuming I understood what was happening or what people were trying to do. Instead, I went to the gemba to see the current condition for myself. Success!

Next comes genchi genbutsu. This is the Toyota principle of teaching by doing directly to the gemba, then making correct decisions, building consensus, and achieving goals.

Both these terms come up over and over again throughout the text. You can’t miss them.

The third is countermeasures. Here’s a passage from the text:

The term “countermeasures” is an important one at Toyota. You will hear there are no solutions, just countermeasures. These are measures that members hypothesize might help counter (reduce) the gap between the desired condition and the current condition. Measures are tested, and if they help to reduce the gap, they are continued until better ones are developed. Proven countermeasures lead to standards–the best we know today until we set a better, perhaps more challenging, standard.

The passage made me evaluate why I’d taken certain actions before. Preflight checks are one great example. I hypothesized that if I had a dry run mode to my application, then started the app in a dry run mode during the deployment pipeline before executing a code change; this would reduce errors created from the combination of configuration and code (i.e., “environment” in the 12-factor app sense). That proved successful in stopping many guaranteed failed deploys. I’ve adopted preflight checks as part of my standard work for years now and, in turn, brought it to any new team I work with.

The Toyota Way also made me reassess my view on standard work. I had been misusing the term. The term appears in the passage on countermeasures and numerous times throughout the text. At Toyota, “standard work” means the best way to do things as we currently understand. It’s a moving target. Standards will change as requirements change, and we discover new ways of working and solving problems.

I think there’s hesitancy in adopting “standard work” in knowledge work (like IT). Detractors see it as a means of stifling people’s creative abilities. I don’t think that’s the case. I consider the standard guardrails. They are proven formulas. Human creativity is not needed to complete a standard procedure. Human creativity is needed to improve the standard. There is a time and place for standard work, just as there is a time for kaizen.

My mistake was miscategorizing “standard work” as “regular work” (or “business as usual”) type work. That is, the things we know we have to do by our position. Writing tests is regular work for developers. There may be (and should be) standard work associated with that, for example, what, where, and how to test specific bits of code. Human creativity comes to the rescue when a new challenge does not fit the standard work. I’ve included a highlighted passage regarding standard work later in this post.

I did learn something new from the book. I learned that I misunderstood a concept entirely. You may have heard anyone on the production line could pull the Andon cord to stop the line. That was my understanding until reading this book. That is not true. Anyone on the line can pull the Andon cord. A team leader responds to the andon pull. They must review the situation and decide if the line should stop.

There are stories in the book about teams adopting the andon cord without having a team lead come and review. As a result, anyone could stop the line, creating chaos. So TIL: an andon pull is like a page; send to someone else for further action.

Highlights

Here’s a grab bag of highlighted passages.

This is a quote from The High-Velocity Edge. The quote appears in the chapter on “PDCA Everything”. Here’s someone reflecting on their image as a leader and problem solver after years in Toyota:

Lesson 1. There is no subsitute for direct observation.

Lesson 2. Proposed changes should always be structured as experiments.

Lesson 3. Workers and managers experiment as frequently as possible.

Lesson 4. Managers should coach, not fix.

I included this passage because it compresses a 350-page book into four sentences. Sure, it’s a lossy compression, but it’s pretty good.

Here’s something different.

Our primitive brain hates uncertainity and drives us to assume we know the right answer or there is a known best way.

This is a great quote for a few reasons. One, it connects to a principle in Deming’s System of Profound Knowledge: understanding of psychology. The author didn’t include “monkey” before “primitive brain”. That would cut down some of the human ego. This leads right into Daniel Kahneman’s work on thinking fast and slow. Our primitive monkey brains (no slight to monkeys) are great at pattern matching and applying known solutions. That’s fast thinking. Slow thinking requires reason and analysis. That’s much harder to do. The quote conveys that our brains will opt for (likely incorrect) fast thinking without proper training.

Practices like genchi genbutsu and scientific thinking are countermeasures to our inate desire to assume we know the answer. Instead, we must discover the correct responses to the challenges before us.

Leveling work (heijunka) is one such challenge. I’ve questioned the prerequisites for lean processes. In other words, can we just start doing this, or do we need to get something in order first? I don’t have the answer. I’m still exploring that question. This passage adds some weight to one side of the argument:

Leveling [heijunka] enables takt (stable rate of demand), which is necessary for doing standardized work and balancing work on the line, which is a requirement for leveled pull from upstream processes and supplier, which leads to minimum inventory, minimum cost, and the best quality.

Here’s another passage that alludes to Deming’s System of Profound Knowledge principle: understanding variation.

It is impossible to improve any process until it is standardized. If the process is shifting from here to there, then any improvement will just be one more variation that will be altered by the next variation. One must standardize and thus stablize, the process before continuous improvements can be made.

It’s as if Liker is channeling Deming directly from The New Economics. “shifting from here to there” is special cause variation. “standardizing” refers to removing special cause variation before doing anything else. “altered by the next variation” is tampering. Deming dedicates an entire chapter to tampering in The New Economics. This passage reinforces the importance of standardized work as the requirement and backstop for improvement. So first standardize and stablize, then improve. This led more questions on the prerequisites for achieving lean.

Here’s a passage from a former CEO on the Toyota Business Practices (TBP) and standardized work. I think this corroborates my position on standard work.

The Toyota Business Practices–a standard approach of business processes and a common language for all of Toyota. Such a standardized approach is not intended to limit an individual’s way of conducting business. Rather, the standard approach provides a basic framework from which the individual can express their unique talent.

The following passage presents a different view of kaizen. This one hit me hard. So much so that I need to highlight it and underline it.

Hansei is really much deeper than reflection. It is really being honest about your own weaknesses. If you are talking about only your strengths, you are bragging. If you are recognizing your weaknesses with sincerity, it is a high level of strength. But it does not end there. How do you change to overcome those weaknesses? That is at the root of the very notion of kaizen. If you do not understand hansei, then kaizen is just continuous improvement. We want to overcome areas of weakness.

Damn. That is one of my favorite passages from the book. This type of thinking shows up time and again in the book. People are always looking for the deeper meaning of their actions. They’re questioning and looking into philosophy. It’s amazing.

Alright, here’s the last one.

Contrary to the notion that lean processes fix problems, the truth is they reveal problems and place a higher burden on leaders, managers, and team members to keep on improving.

This quote resonated with me because it reveals that leadership is a real issue. How often has the responsibility incorrectly fallen on frontline people when management assumes a new way of working is a magic bullet that solves all the problems?

FAQ

How can I support you?

The best way is with a paid subscription to Software Kaizen. Your support goes into producing more Software Kaizen and the Small Batches podcast. Sharing this post or commenting on it is great, too.

What should I study next?

I recommend The Birth of Lean to learn how Toyota discovered these principles. I recommend Wiring the Winning Organization for another take on the lean mental model. Also, refer to my study guide for related works.

What is your favorite principle?

Applying Principle Seven (use visual management) has made the most difference for me and my teams. I leaned hard into Miro boards. Now, I can not go back. Doubling down on visual management has made planning, communicating, and doing work much easier.

This is straight out of Deming’s The New Economics and the System of Profound Knowledge. This should be no surprise since Deming worked extensively with Toyota and other Japanese companies. See Deming's meetings with JUSE in the late 1940s and 1950s. His story is covered in Deming’s Journey to Profound Knowledge.

See “capability one: system design and operation” from The High-Velocity Edge. Capability one groups The Toyota Way principles one, two, three, four, and five.

This is also discussed in-depth in The High-Velocity Edge under capability one: system design. The idea comes from the legendary Taiichi Ohno.

See “Capability Two: Problem-Solving” from The High-Velocity Edge. This goes hand-in-hand with jidoka (automatically detecting defects and other failure scenarios). Also, refer to “Amplification” in Wiring the Winning Organization

See “Capability Four: Develop High-Velocity Skills in Others” from The High-Velocity Edge. Refer to The Toyota Kata by Mike Rother for more on leaders as coaches.

Direct reference to The Toyota Kata. It’s great to see Rother’s work in the principles.

This is why I named my podcast “Small Batches”. Consistent improvement over time. Get 1% better every day. Results compound over time. Working in large batches is riskier and more difficult than working in small batches. So, reduce the batch size, stay small, and keep iterating.

I think there is an overlap between Zen Buddhism and the Gemba idea. I don’t think this is an accident either. I think a confluence of aspects in Japanese culture and Buddhism led to “The Toyota Way”. First, Japanese culture tends to take a long-term view, thinking about one or two generations down the line. They’re also group-oriented and strive to exceed in many things. Japanese work ethic is legendary. Buddhism encourages people to think of the interconnectedness of all beings. Buddhist philosophy is more common in Japan than it is in the West. I’m speculating here, but this may be why it was so difficult for Western companies to truly grok The Toyota Way.

Liker thinks there is a connection as well. He suggests the communal nature of rice farming and cultural exposure to Buddhism. It turns out that Saikichi Toyoda was a Buddhist himself.